No one tells you this, but cash isn’t the biggest thing you need to kick off a manufacturing startup—it’s about resourcefulness. Think about it: a good chunk of famous companies started out broke. They didn’t just magically get loans or funding; most hustled their way in, scraping together bits and pieces.

If you’re eyeing the manufacturing world but your account balance says “try again,” don’t sweat. Plenty of smart hacks get you moving toward making stuff without piles of cash. Sometimes all you need is a sharp idea and the guts to pitch it before you even build your first product.

Let’s get something out of the way: you won’t need fancy equipment or a 5,000-square-foot warehouse on day one. Start with what you’ve got. Maybe you can rent machines by the hour, work from a shared makerspace, or even partner up with someone who has tools collecting dust.

- Ditch the Cash Myth: The Real Startup Cost

- Turning Ideas Into Income

- Creative Ways to Get Equipment and Space

- Finding Your First Customers on a Shoestring

- Scaling Up Without Sinking In Debt

Ditch the Cash Myth: The Real Startup Cost

Most people think launching a manufacturing startup needs thousands sitting in the bank. That’s just not true anymore. Zero upfront cash is how plenty of new businesses start, especially now when you can rent, borrow, or even barter for almost anything.

If you look around, tons of makerspaces, community workshops, and local colleges offer access to tools and equipment for a small fee or even free during certain times. You don’t have to own everything to get started. Renting by the hour or teaming up with another startup can cut your real costs down to almost nothing.

“The biggest mistake entrepreneurs make is thinking money is the only barrier. Start with hustle, not capital.” – Ash Maurya, author of Running Lean

Let’s get specific about where money actually goes. Here’s what most people think they need to spend money on, compared to what’s really needed at day one:

| Perceived Startup Expenses | What You Actually Need |

|---|---|

| Buy expensive machines | Rent machines, use public makerspaces, or borrow |

| Lease a large factory | Start in a shared workshop or small garage |

| Hire a full-time staff | DIY, partner with freelancers, or barter skills |

| Stock tons of raw materials | Order on-demand, use supplier credit, or buy small batches |

Even with all these hacks, you’ll want to be prepared for some costs—like insurance, basic materials, or small-scale prototypes. But you’re looking at a few hundred bucks, not thousands. And often, you can cover these with pre-orders or customer deposits (we’ll talk about that soon enough).

- Skip massive loans: focus on creative workarounds.

- Find local programs or contests that offer grants or space for new manufacturers.

- Tap into online communities—many pros love helping newcomers with unused resources.

The real startup cost is stubbornness, a few connections, and the guts to start before you’re "ready." Money is just one piece, and not even the biggest one these days.

Turning Ideas Into Income

Turning a manufacturing idea into actual cash might sound impossible if you start with nothing. But people do it—every day. Here’s the wild truth: you don’t need a finished product in hand to make your first sale. Crowdfunding platforms like Kickstarter and Indiegogo have helped thousands of newbies start up, with over $6.5 billion raised on Kickstarter alone by 2024. That means a killer pitch video and a prototype can do the heavy lifting for you.

Hot tip: Pre-sell your product. Offer early discounts or bonuses for customers willing to back you before you’ve even shipped your first item. You can also find businesses looking for just-in-time manufacturing, which basically means they order and pay for stuff only when there’s actual demand. That’s cash up front—before you spend on parts or labor.

If you’re still wondering where to find these early buyers, try tapping your network or specialized Facebook groups. On LinkedIn, there are groups dedicated to every imaginable manufacturing startup niche. Share a mockup, collect feedback, and then ask if anyone’s willing to become your first customer or pilot partner. It feels weird, but a startling number of first deals come this way for beginners.

Check out this quick comparison of ways people have earned that first dollar BEFORE production:

| Method | What’s Needed | Risk Level |

|---|---|---|

| Pre-orders | Prototype & online pitch | Low - if transparent |

| Crowdfunding | Campaign video, early supporters | Moderate - need to deliver |

| Business Partnerships | Sample, relationship building | Steady - longer to secure |

| Joint Ventures | Complementary partners, shared vision | Medium - share control |

Don’t try to reinvent the wheel alone. There are even accelerator programs like Y Combinator or Techstars, where you can bring just an idea, get mentoring, and sometimes score initial funding. Their acceptance rates are low, but if you get in, you’re halfway there. The bottom line: with a strong pitch, a sample, and some nerve, your idea can open doors and start paying for itself, way before you worry about inventory or payroll.

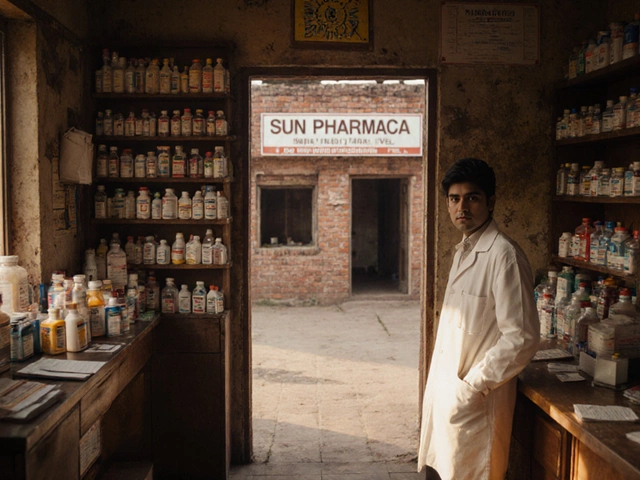

Creative Ways to Get Equipment and Space

This is where most folks get stuck: equipment and workspace. Heavy-duty machines look expensive, but there's no rule that says you must buy brand new gear. The trick is to think outside the box, or more like, outside your wallet.

First, check out local makerspaces and fabrication labs. These spots are popping up everywhere and are built for people who need tools but can't afford them. For a small membership fee—or sometimes just by helping out—you can access 3D printers, laser cutters, CNC machines, and more. Platforms like MakerHub and FabLab post locations near you.

Another move is to rent equipment by the hour or day. Sites like EquipmentShare or PeerRentals connect you to people and companies willing to lend out their gear. It's way cheaper than buying, and you pay only when you actually have an order or prototype to make.

Don't overlook partnering with universities or vocational schools. They often look for real-world projects for students and have killer workshops. Sometimes, you can use their equipment in exchange for mentoring a student or taking part in a class project.

This isn’t just theory. A report by the U.S. Small Business Administration found that almost 23% of small manufacturing startup founders managed to launch by using shared workspaces or borrowed equipment in their first year (2023 data). That means you're not alone in going scrappy.

"Don’t get stuck chasing perfect conditions. Start with what you can borrow, rent, or barter. Your first customer won’t care if the product came from a fancy new factory or a borrowed press in someone’s garage." — Tom Kelley, IDEO partner and innovation guru

Hunting for free or cheap gear? Here’s a quick list of real-world moves:

- Search Craigslist, Facebook Marketplace, and industrial auctions for used machinery—small manufacturers often upgrade and sell for cheap.

- Join local manufacturing and business networking groups; many old-timers have equipment they barely use and are open to partnerships or rentals.

- Check out government grants or non-profit business incubators—they sometimes provide low-cost access to workspace and equipment for startups.

| Method | Average Cost (USD) | Commitment |

|---|---|---|

| Makerspace Membership | $50-$200/month | 1-12 months |

| Hourly Equipment Rental | $10-$80/hour | As needed |

| Used Equipment Purchase | $500-$5,000 (one-time) | One-time |

| Borrow/Barter Partnership | Sometimes free | Case by case |

The bottom line: don’t let high prices keep you on the sidelines. Plenty of successful businesses were launched on loaned gear from a garage or a shared shop. Focus on building, not owning, and soon your biggest problem will be keeping up with new orders.

Finding Your First Customers on a Shoestring

Here’s the deal: you need buyers before you can even think about big runs or production lines. No money? No problem—scrappy beats flashy every time, especially when you’re starting out in manufacturing startup.

Instead of waiting for people to come to you, go where your customers hang out. If you’re making something simple like custom shirts or small parts, hit up local business events or online groups. LinkedIn and Facebook groups for small businesses are full of folks looking for problem solvers. Slide into DMs, reply to posts, join the conversation. You don't need a fancy website to sound like you know your stuff.

Want to make it even easier? Try preselling. Preselling just means you pitch your product to a customer, get payment or a deposit upfront, and use that money to cover your costs. Sites like Kickstarter have moved almost $7 billion for creators this way, and manufacturers aren’t left out. If you prefer a smaller scale, reach out individually—send emails to targeted businesses or make a basic Google Form order sheet to track interest. One classic example: Plexus, now a billion-dollar company, started this way by building what customers ordered before having a factory or stock.

- Find local businesses who need what you’re offering and start conversations.

- Use LinkedIn to offer quick demos or even free samples to your first prospects.

- Offer a beta run or prototype discount if a buyer is willing to pay upfront or provide a testimonial.

- Ask for referrals as soon as one customer is happy, even if it’s just for a small job.

Here’s a quick look at practical ways to reach customers with almost no budget:

| Low-Cost Tactic | Estimated Cost (USD) | Success Rate |

|---|---|---|

| Direct messages on LinkedIn | 0 | 20% reply rate |

| Facebook marketplace listing | 0 | 15% interest rate |

| Email campaigns to local businesses | 0-20 (if you use a tool) | 10-20% open rate |

| Local small business meetups | 0-50 (entry fee) | High—face-to-face |

| Kickstarter pre-sales | ~50 setup | Varies, but $8,000 is average first-time raise |

Don’t hide behind excuses. Hunt down your first sale, even if it’s small. Word-of-mouth travels way faster and cheaper than any ad campaign when you’re starting from zero.

Scaling Up Without Sinking In Debt

Once you land your first few orders and see things moving, it’s easy to think you need to pour cash into bigger equipment or a snazzy factory. Don’t fall for that. Getting too excited and taking out a massive loan can end up burying your manufacturing startup before it ever grows legs.

It’s smarter to scale in bite-sized steps. Use what’s coming in from early sales to reinvest in your tools or work space. This is how a lot of small manufacturers grew up, not by gambling on debt, but by letting the business fuel its own growth. Some founders use the 70/30 rule: put 70% of your profits back into operations and keep 30% for emergencies or slow months.

If you really need a cash boost, crowdsource it—platforms like Kickstarter and Indiegogo are packed with real people funding small-scale manufacturing startups that show transparency and a clear market. You get the backing without bank loans and the best part is, you don’t give up equity or end up with high-interest bills.

Outsourcing can also keep your costs realistic. You don’t need to own every piece of machinery. Tons of new businesses use contract manufacturing or partner with small plants that have extra capacity. This trims your overhead and means you pay only for what you actually produce.

Here’s a quick look at some real numbers about debt and manufacturing startups:

| Source | Debt Level | Startup Outcome |

|---|---|---|

| SBA Report (2024) | Less than $10K | 68% survived 3+ years |

| SBA Report (2024) | $10K - $100K | 45% survived 3+ years |

| SBA Report (2024) | Over $100K | 23% survived 3+ years |

The data’s clear: lower debt equals better odds. So as you expand, prioritize lightweight costs and explore funding that doesn’t drag you under. Keep your manufacturing startup lean until you have the volume and steady orders to support bigger moves.

Write a comment