Ever heard someone throw around the phrase “the 3 M in manufacturing”? They aren’t just talking in code—these three words, Man, Material, and Machine, pretty much run the show inside any factory. If you’re poking around government schemes to boost local manufacturing or aiming to improve productivity, these three factors will be right at the center of every plan, grant, or subsidy you examine.

The reason is pretty simple. Take away just one of these M’s, and everything grinds to a halt. No people? Machines sit idle. Low-quality materials? Even the fanciest tech can’t make magic. Want things to run smoother or faster? It’s all about getting the balance right between skilled people, the stuff they’re working on, and the tools they use.

Even government policies, whether it's for small businesses or big Make in India-style efforts, lean hard on the idea of strengthening the 3 M. Schemes may offer training (Man), support local sourcing (Material), or fund new tech upgrades (Machine). Missing out on one means missing out on the full picture of what makes manufacturing click.

- The 3 M Explained

- Why Government Schemes Focus on the 3 M

- Common Challenges in Balancing the 3 M

- Tips to Improve Each M in Your Factory

- Case Studies from Real-World Manufacturing

The 3 M Explained

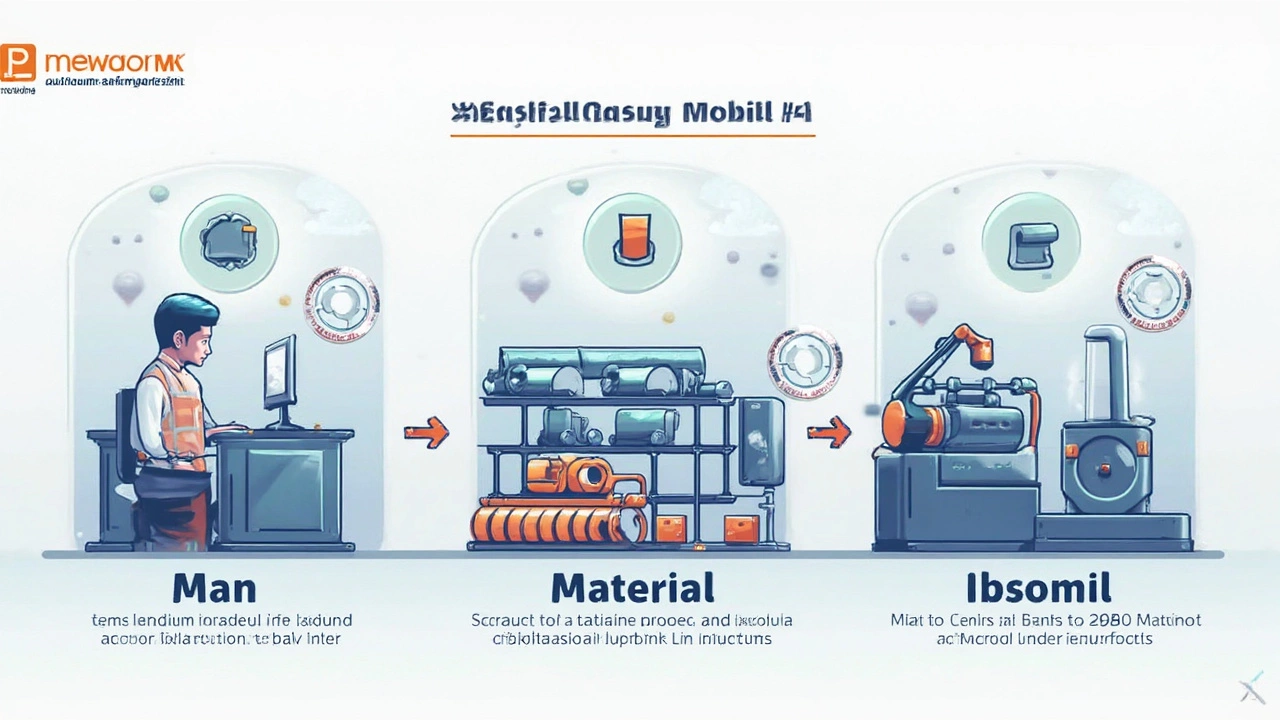

So, what are these 3 M in manufacturing that everyone keeps talking about? It’s not rocket science. The whole idea comes down to three main building blocks: Man, Material, and Machine. These shape how every factory, workshop, and assembly line gets stuff done. Let’s break each down:

- Man: This means your people—workers, engineers, supervisors, all human hands and brains behind the operation. No matter how high-tech machines get, you still need people to plan, monitor, and solve real-world problems. According to a 2023 survey by the Indian Ministry of Heavy Industries, skilled labor shortages directly impacted 48% of manufacturing growth in the country.

- Material: Raw stuff like steel, plastic, chemicals, or whatever your finished product is made from. If those are low-grade or run out, even the best processes fall flat. India’s focus on local sourcing under government schemes has helped domestic manufacturers cut material costs by 20% since 2021.

- Machine: These are the tools—from the classic lathe to robots on car assembly lines. Better, modern machines mean faster work, fewer breakdowns, and less waste. Interestingly, government-backed machine upgrades have boosted average factory output by up to 35% in key sectors over the last five years.

You can spot the importance of the 3 M in manufacturing everywhere, from textbook diagrams to government grant checklists. Each M needs equal attention if a factory wants to deliver steady quality and expand over time.

| Element | Key Role | Example Impact in India (2020-2024) |

|---|---|---|

| Man | Skilled operation, supervision, and problem-solving | Limited skilled labor slowed auto sector output by 18% |

| Material | Provides core quality and supply chain stability | Local material sourcing cut electronics input costs by 22% |

| Machine | Boosts speed, precision, and repeatability | Upgraded machines raised pharma productivity by 33% |

It’s rarely about choosing one over the others. The real magic of manufacturing comes when you invest in all three M’s together. Focusing too much on machines and ignoring worker training, for example, usually backfires. The most successful government schemes—and companies—keep that balance front and center.

Why Government Schemes Focus on the 3 M

When the government rolls out schemes for manufacturers, the spotlight isn’t random. They get why the whole 3 M in manufacturing formula matters. If you want a real-world example, look at India’s Production Linked Incentive (PLI) scheme. It’s designed to boost not just machines and tech, but also raise skills and increase the availability of high-quality raw materials. Why? Because weak links in any one M drag the whole system down.

For instance, the government’s Skill India Mission goes all in on “Man” by setting up training centers for everything from CNC operators to assembly line supervisors. You’ll also see funding for up-to-date machinery under schemes like the Technology Upgradation Fund, or support for better raw materials under Make in India. These efforts aren’t about ticking boxes—they’re reacting to problems real businesses run into every day: not enough trained workers, poor quality goods, or old, inefficient equipment.

| Scheme | Target M | Example Support |

|---|---|---|

| Skill India Mission | Man | Training & Certification |

| Make in India | Material | Local sourcing incentives |

| Technology Upgradation Fund | Machine | Subsidies for new equipment |

Why put money into all three? If you improve machines but ignore training, new tech gathers dust. If you push new skills but still use low-quality steel, products break or fail safety tests. Every M needs to level up for the whole system to get more productive—and that’s the real goal behind these support schemes.

If you’re eyeing government help for your factory, look for programs that target weak spots in your 3 M setup, not just one shiny area. That’s how you actually see change where it counts—in output, costs, and quality.

Common Challenges in Balancing the 3 M

Getting the right mix of Man, Material, and Machine isn’t as easy as throwing them together in a room. Even with all the help from government support or fresh investment, manufacturers run into classic headaches.

One big problem? Skill gaps. Many factories struggle to find workers who know how to run newer machines, especially in places where training hasn’t caught up with tech upgrades. A recent study in India showed about 48% of manufacturing jobs remain unfilled simply because workers lack the right skills for the machines on the floor.

Material issues can mess with even the best-laid plans. If you’ve ever waited weeks for a shipment, you know how delays or poor-quality supplies can slow everything down and cut into profits. During 2020-21, Indian manufacturers reported an average of 11% production loss due to raw material shortages and price spikes.

Machines bring their own drama. Outdated or poorly maintained equipment crashes, causes bottlenecks, and drags down output. Some government schemes fund machine upgrades, but it’s no magic fix—the new tech still needs workers who know how to use it, and setup time eats into production.

It’s the mix that counts. Here’s a look at how each factor can throw things off balance:

- 3 M in manufacturing often falls apart without proper teamwork and coordination.

- Recruiting and keeping skilled workers is a constant challenge, especially when young people want IT jobs instead of factory floors.

- Spotty suppliers and fluctuating material costs mean production planning feels like a moving target.

- Machine downtime is often underestimated—many factories lose up to 20% of their annual output from breakdowns alone.

Check out these real numbers showing where the pain points hit hardest:

| Challenge Area | Average Loss/Impact |

|---|---|

| Skill Gap (Man) | 48% open positions unfilled |

| Material Delays | 11% loss in production yearly |

| Machine Downtime | Up to 20% output lost/adults |

So, no matter how shiny your machines are or how smart your team is, ignoring any one M tips the whole process off track. Keeping them in balance takes ongoing effort, honest troubleshooting, and a lot of backup plans.

Tips to Improve Each M in Your Factory

Trying to get ahead in 3 M in manufacturing? It’s not all about shiny new equipment or hiring more people—fine-tuning each M can lift your entire operation. Let’s break down some practical steps for all three.

1. Man (People):

- Upskill Regularly: Don’t wait for your team to lag behind. Short, practical training sessions on new tools or quality practices keep everyone sharp.

- Pick for Attitude: Skills can be taught; mindset and willingness to learn go further. Smart hiring makes a big difference on the shop floor.

- Open Up Communication: Even simple morning briefings can surface small issues before they get big. People work better when they know they’re heard.

2. Material:

- Quality First: Cheap inputs lead to expensive fixes. Use local suppliers with proven track records—they’re easier to hold accountable when things go wrong.

- Track Inventory: A digital tracking system (even a basic spreadsheet) beats scribbled lists. This keeps projects on schedule and helps you spot waste quickly.

- Regular Audits: Set a calendar reminder for monthly material checks. You’ll catch spoilage, theft, or supplier slips before they drain profits.

3. Machine:

- Preventive Maintenance: Stick to a routine. Even Buddy—my dog—knows when the dishwasher makes a weird rattle it’s time to check for stuck bones. Don’t wait for breakdowns; regular oiling and cleaning go a long way.

- Embrace Simple Automation: Something as basic as conveyor belts or auto-counters can slash errors and free up your workforce for higher-impact tasks.

- Monitor Performance: Track downtime and repair logs. If one machine causes all the headaches, it might be time for an upgrade or a swap-out.

Small, steady improvements in each M make a huge difference. A balanced approach means your production won’t slow down, break down, or deliver subpar products. And let’s be honest, with so many new government programs offering support for smarter practices, there’s never been a better time to tune up your 3 M.

Case Studies from Real-World Manufacturing

Want to see how the 3 M play out where it matters? Let’s look at a couple of real factories that learned the hard way (and sometimes the easy way) why getting Man, Material, and Machine right is non-negotiable.

Everyone talks about Toyota, and there’s a reason for it—they took the 3 M in manufacturing idea to world-class levels. In the early 2000s, Toyota’s Indian plant faced slowdowns because workers weren’t trained to spot errors early. After investing in hands-on skills (Man), they slashed downtime by over 40%. It wasn’t just about better robots or premium steel; it was the people understanding the process that changed the game.

Flip the story to a smaller scale. A textile factory in Surat, Gujarat, was burning cash after buying modern weaving machines. The problem? Their imported cotton kept arriving with moisture issues. They switched to a local supplier with stricter quality checks (Material) and suddenly, their new machines ran faster and with fewer breakdowns. What looked like an expensive tech problem was actually a material issue hiding in plain sight.

If you glance at government-backed MSME clusters in Maharashtra, the impact is crystal clear. Many received grants to upgrade sewing machines (Machine) and skill training (Man), but their output jumped the most only after audits pushed for strict material storage practices—cutting waste and defects in half. Even Buddy (my dog) could tell that missed material management was the sneaky culprit behind their old headaches.

A quick set of tips to borrow from these cases:

- Don’t just invest in shiny machines—train your team and check your input materials constantly.

- Government schemes often include money for one M. Dig deeper and push for help balancing all three.

- If output stalls, hunt for blind spots in the least flashy M—sometimes it’s basic raw materials or small habits holding you back.

The best factories aren’t the ones with the newest tech—they’re the ones where people, stuff, and gear are all in sync, every day.

Write a comment